- Sector

- Healthcare

- Project type

- New build

- Client

- Jersey NHS

- Contractor

- Brady and Gallagher

- Products used

- Air socks

Requirement

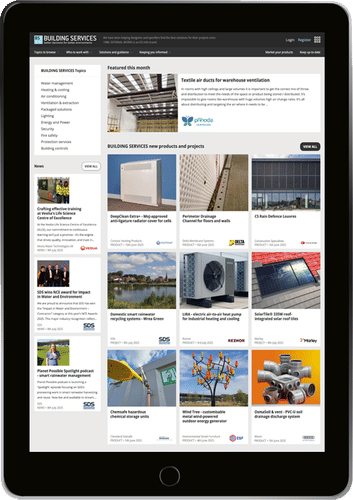

In response to the COVID-19 outbreak, a fast-build hospital was specified for Jersey and Prihoda was able to pull off a bespoke design for the ventilation system in the shortest of time frames.

Timeframe

The eye-watering timeline for this project ran from the decision to have a field hospital on 2 April, and saw the construction of an aluminium-framed semi-rigid panelled building, (erected by a team from the Netherlands in 9 days), with the complete fit-out, through to the anticipated opening on 4 May.

Prihoda was selected to supply fabric ducting for the temporary building.

The ventilation system and its bespoke manufacture

Once the electronic design reached the team at the factory at Prihoda HQ in Hlinsko in Czechia, on Friday 17th April, they were briefed on the urgency of the job. Michal, Head of Production, sourced the fabric from existing factory supplies and the perforation of the fabric was done by the laser machines over the weekend, so that the fabric ducts could be sewn together on the Monday.

The ducts were checked by the output inspection department and packed into boxes ready for transportation to the UK. As explained by Zdenek Prihoda, CEO: "It is a chain of simple steps but not one element needs to go wrong".

Once on site, the air socks were installed with a simple rail system and connected to the ventilation equipment by the Jersey-based M&E contractors Brady and Gallagher.

Zdenek added: "It is our duty and I feel happy we had a great opportunity to help!"

Indeed, this collaboration shows how good communication in all elements of the supply chain have brought about a solution to just one small element of the fast-paced and huge effort needed to construct a Nightingale Hospital.